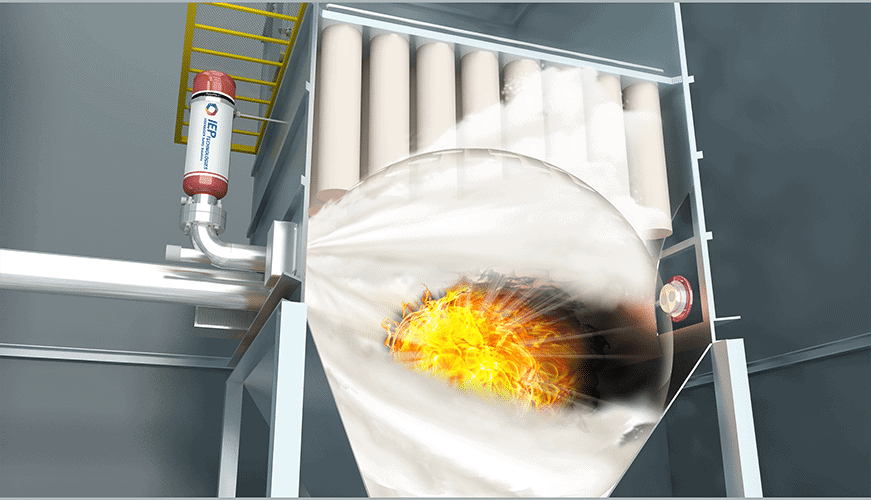

There are many types of dust explosion protection, each with its own advantages. The most common types are listed below.

-Overpressure containers: Overpressure containers are similar to staunton boxes, but they also have a pressure gauge to measure the pressure inside the container in case of an explosion. The pressure can be increased if necessary to prevent particles from escaping.

If you are looking for a Dust Explosion Protection service then you may visit coopatex there are lots of services available as per your needs.

Image Source : Google

-Dust collectors: A dust collector is a machine that removes small amounts of dust every minute or so from an area where an explosion may occur. This keeps particles from becoming an explosive mixture and helps protect personnel who may be in close proximity to the dust source.

-Baffle plates: Baffle plates are similar to overpressure containers, but they have holes in them that allow air to flow around particles so they don't form an explosive mixture.

How to Protect Yourself from a Dust Explosion?

Dust explosions can be dangerous and debilitating, so it is important to know how to protect yourself from them. Here are some tips:

1. Use a dust mask when working with dust. Dust masks do not just protect you from the particles in the air they also filter out large particles that could cause a dust explosion.

2. Keep your work area clean and free of debris. Clean up any messes immediately, and keep your work area clear of any unnecessary items, such as furniture or boxes. This will help prevent accidental sparks that could lead to a dust explosion.

3. Use caution when handling dust. Be sure to wear gloves, eye protection, and a face shield if necessary. Avoid touching your eyes or skin until you have washed your hands thoroughly.